Track-type Intelligent Inspection System

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

|---|---|

| Min. Order: | 1 Bag/Bags |

| Delivery Time: | 180 Days |

| Packaging: | wooden packing |

|---|---|

| Brand: | DFMC |

| Transportation: | Ocean,Land,Air |

| Place of Origin: | DANDONG |

| Port: | Dalian,Shanghai,Tianjin |

Product Description

Track-type Intelligent Inspection System

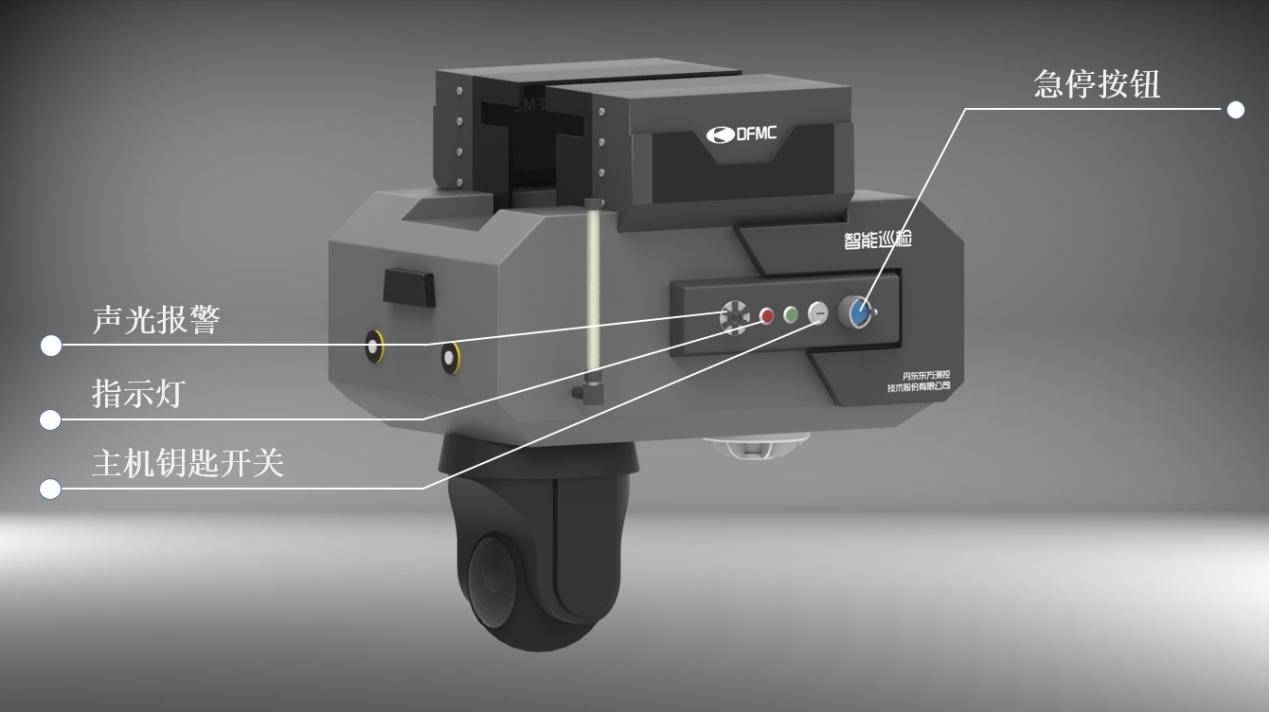

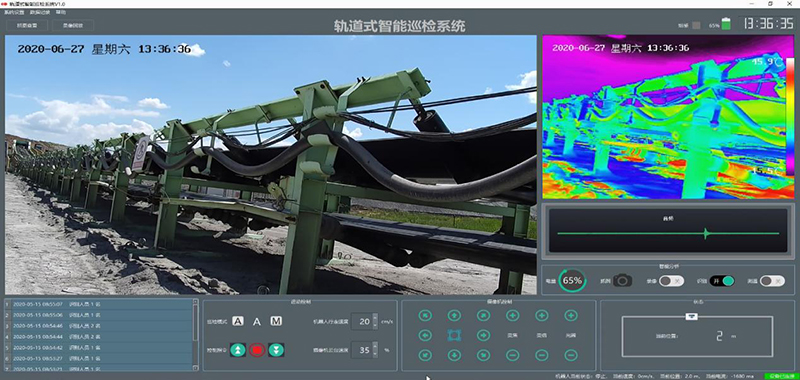

Track-type Intelligent Inspection System is a product developed by DFMC to realize intelligent and unmanned factory, which can replace manual inspection of belt transportation system, underground roadway, power distribution room, production workshop and other locations. The product relies on the camera and a variety of sensors carried by the inspection robot, which can run back and forth on a single track or continuously on a circular track to observe and judge the production environment, equipment, process conditions, production safety conditions and abnormalities.

无线充电Wireless charging

The Track-Type Inspection System can identify and judge the following:

1. Equipment problems: detection, such as belt idler falling, high temperature of idler, Belt Conveyor deviation, high temperature of motor or bearing, abnormal noise of equipment, etc.;

2. Process problems: detection of belt stacking, sprinkling, pipe cracking, etc;

3. Production safety problems: be able to detect smoke, fire, fire hazards, toxic gases, dust concentration, personnel intrusion in dangerous areas, personnel calling-for-help identification, personnel not wearing safety helmets and other PPE according to the requirements;

The Intelligent Robotic System is reliable and easy to operate. It has two working modes: automatic and manual. In the automatic mode, the inspection can be carried out continuously according to the set operation action and pan tilt action; in the manual mode, it can be controlled manually. The device also carries an intercom system, which is convenient for on-site meeting, calling and other work. In addition, the device also has the functions of capture, video recording, recording, automatic charging, historical data query, regular generation of inspection report, emergency alarm and so on.

The main technologies deployed in the system are as follows:

1. Motion control technology: with the servo control technology, the motion of the equipment is more flexible, and the reliability and service life of the equipment is longer thanks to the servo or stepping system;

2. Wireless transmission technology: the device uses wireless technology for data transmission and control command interaction. 5G technology can be used to enable the device to collect images with higher definition and lower data transmission delay; 3. Artificial Intelligence technology: in the aspect of image recognition, advanced deep learninging technology is adopted, and GPU parallel accelerated computing technology is used to deploy the deep learning network. The recognition speed of each picture can reach 10 ms. We are training the neural network according to the Element Analyzer equipment, production and other elements of the industrial site, and the recognition accuracy is also improving.

Main specifications of Inspection System Robot:

(1) Dimension: length 400 mm × width 300 mm × height 500 mm

(2) Weight: less than 20 kg

(3) Power supply mode: battery or rail power supply

(4) Mechanism: hanging guide rail

(5) Speed: 0.2-1 M / s adjustable

(6) Turning radius: horizontal ≥ 1.5m, vertical ≥ 0.8m

(7) Climbing capacity: ≤ 30 °

(8) Mileage: 4km (fully charged, continuous operation of horizontal roadway)

(9) Charging time: 1 ~ 1.5h

(10) Protection: IP65

(11) Positioning: coding positioning

(12) Positioning accuracy: ≤ 10cm

(13) Manual control: available

(14) Power supply voltage: DC24V

(15) Power: DC motor

Parameters of dual spectral thermal imaging camera of inspection system:

(1) Focal length (lens): 25mm

(2) Temperature measurement range: - 20 ~ 150 ℃

(3) Abnormal temperature alarm function

(4) Fire source detection distance (based on 2M × 2m fire source): 1500m

(5) Field angle: 11.2 °× 14.9 °

(6) Visible light lens: 4.8 - 153mm

(7) Infrared irradiation distance: 100m

(8) Support optical fog transmission

(9) Visible light resolution: 1920 * 1080

(10) Weight: 3.9kg

(11) Horizontal direction 360 ° continuous rotation, vertical direction - 5 ° ~ + 90 °

(12) Operating temperature and humidity: - 40 ℃ ~ 70 ℃, less than 90%

(13) Protection: IP66

(14) Power supply voltage: DC48V

Product Categories : Inspection System